Sector Overview

Bowen Fluid Engineering has worked extensively in the oil and gas sector to assist companies in the proper care and maintenance of equipment and parts. We also provide technical advice on how to dispose of harmful substances and are highly experienced in hot oil flushing.

As more scrutiny is placed on the practices of oil and gas companies it is more essential now than ever that proper, regulated procedures take place on-site. Machinery and equipment used in the oil and gas sector must be up to the industry standard, meaning regular maintenance, repairs, pressure tests, system cleaning and flushing must be carried out. It pays to perform regular maintenance and preventative inspections to eliminate problems before they occur.

To partner with an experienced oil and gas engineer and to improve the functionality of your lube oil systems, get in touch with Bowen Fluid Engineering today on 01383 413130.

Benefit from an Experienced Oil & Gas Engineer

Bowen Fluid Engineering has formed many successful partnerships with companies within the oil and gas sector. Over our 20+ years within the industry, much of our core work has come from this well-established sector.

A prime example of our oil and gas experience is the project undertook with TMFC. Our team was appointed by TFMC to provide the maintenance and repair of high pressure Grayco air driven pumps and injection rams used in the application of subsea insulation coating of subsea XT’s and associated systems. In addition, we also designed a bespoke mixing gun assembly, using components that are more reliable and easier to procure in order to replace the original design, which was only available from the USA. This helped save the client both time and money and ultimately provided a more reliable unit.

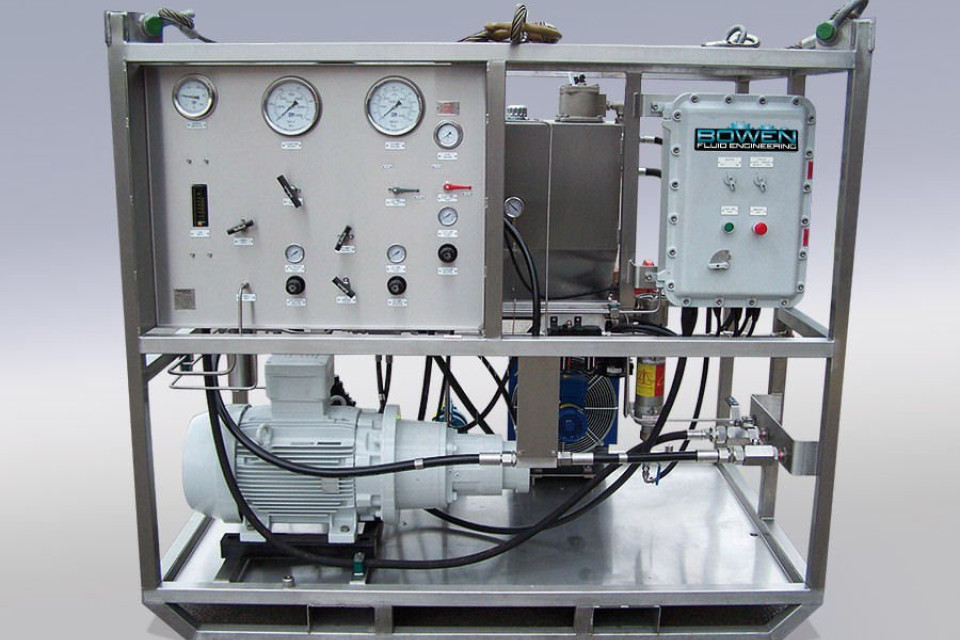

Our team have also been engaged by Oceaneering to carry out extensive hydraulic services, from maintaining and servicing specialist large test bed equipment used to carry out quality and reliability testing on subsea umbilicals. We designed and manufactured a bespoke hydraulic power unit, including the supply of in-house manufactured and tested interconnecting hoses and fittings.

This project, along with many others, allows us to work with our clients closely, sharing our experience and skills to satisfy their needs and wants when it comes to looking after their assets.

Not only will we always work to the client’s specifications in providing, maintaining, and installing parts, but we can also offer our advice on how to improve system reliability, and how to properly look after hydraulic systems. We can also assist with industry-standard practices around hot oil flushing, system flushing, piping and hose requirements in the oil and gas industry.

Choose Bowen for your Oil & Gas Needs

Maintaining equipment, parts and equipment used in the oil and gas sector is essential for the long-term success of any project.

Many of our engineers have come from the oil and gas sector, with a combined experience of over 60 years in the offshore industry. The Bowen team are highly experienced in working to the high level of safety required in these types of bespoke projects.

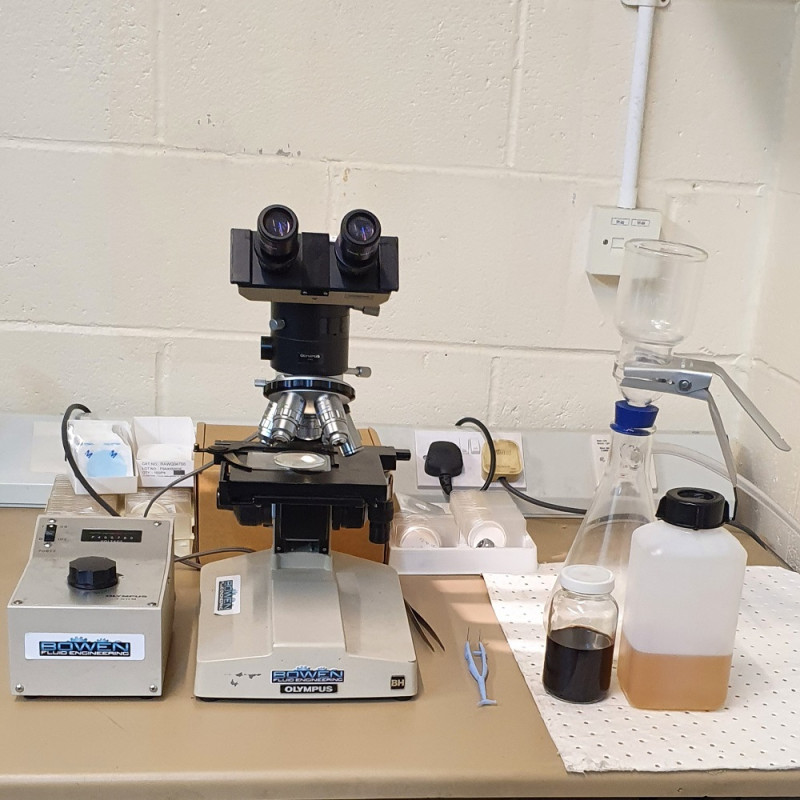

The basic prescription for hydraulic maintenance is prevention. If you keep contaminants out of hydraulic systems, you will avoid nearly all common problems and failures. Our engineers can help you identify weaknesses in your systems, and help you to cure persistent problems with your hydraulics to ensure maximum efficiency, safety and longevity.

Allow us to service, repair and improve your hydraulic systems whilst also enhancing your machinery and working practices.

Contact the team at Bowen today to benefit from our vast experience in the oil and gas sector.

Hydraulic Solutions

Bowen offers a variety of helpful services to our clients in the oil and gas sector. Our hydraulic solutions are always carefully considered with the needs of each client in mind. We offer cost-effective solutions and can help you and your team implement a care and maintenance program to ensure the longevity of your hydraulic machinery.

Using our 20+ years of experience, our team provides the highest quality of services to ensure your hydraulic machinery is working correctly and that your company is following the best practices in this highly competitive sector.

Our Oil & Gas Services

The oil and gas services we can readily offer include:

- hot oil flushing of complete piping assemblies and systems

- The overhaul of hydraulic systems and associated components

- Chemical cleaning of contaminated systems

- Diesel and fuel water removal and polishing

- Carrying out planned maintenance on all hydraulic and piping systems

- Flushing and contamination removal from turbines and compressors

- Reliable pressure testing of rebuilt systems

- Pipework and flushing to NAS, SAE, and ISO standards

- Top drive system flushes

- Hose repair and replacement

- Repair, maintenance and installation of hydraulic power units

- The upgrading of filtration assemblies

- Bespoke filtration advice and guidance