Service Overview

As an experienced team of engineers, our team at Bowen Fluid Engineering has the equipment and expertise to execute high-quality high velocity hot oil flushes for your hydraulic tanks, pipework and systems around Scotland and beyond.

With a fantastic track record of satisfied customers, our friendly service coupled with our professionalism and skill makes us one of the most reputable teams in the country for all of your hydraulic needs.

We understand that your hydraulic system is vital in the running of your business. That's why we always endeavor to provide a speedy service that will get your machine working to an impeccable standard.

What is high velocity oil flushing?

In order to meet oil system cleanliness specifications, you will need to safely execute a high velocity oil flush on a regular basis. A professional hot oil flush will remove system contamination from the critical components of your lube oil systems, while rapidly removing the contaminants that naturally accumulate through fluid systems. This improves performance and pre-emptively minimises downtime.

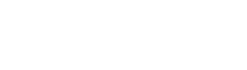

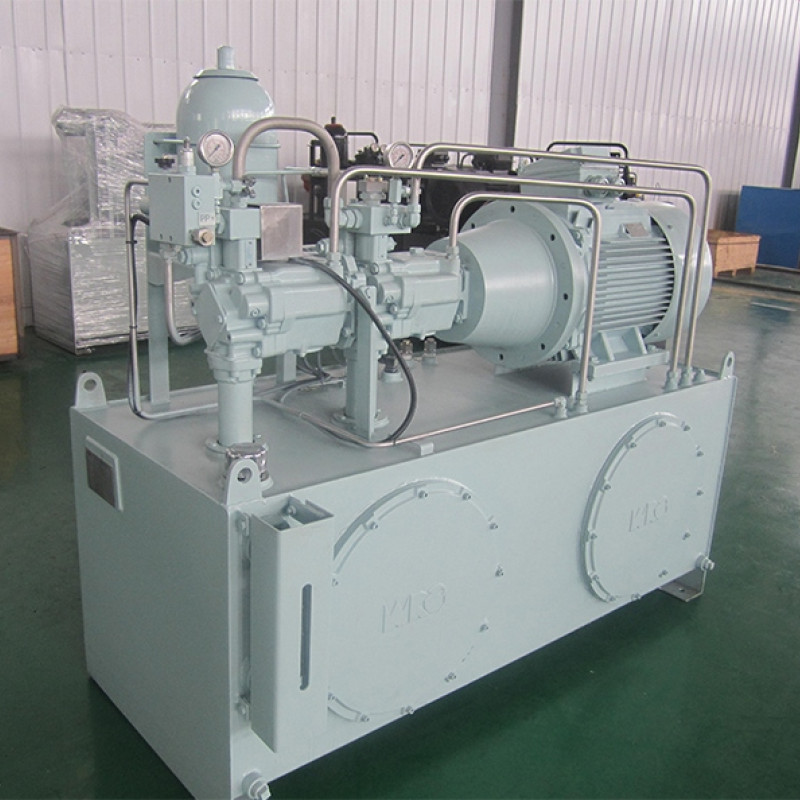

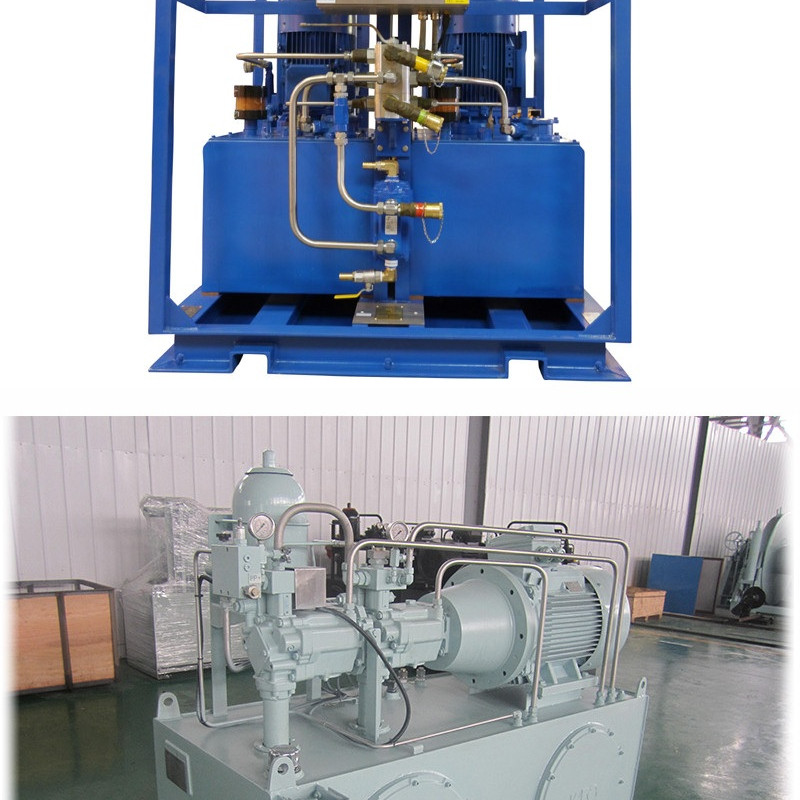

At Bowen, we have state-of-the-art high flow filtration equipment and experienced technicians to perform a wide array of filtration and flushing services at your job site.

By circulating hot oil or a flushing fluid through the piping of a system at a very high flow rate, turbulent flow can be achieved, which dislodges particles that would otherwise cling to the walls during laminar flow. These particles are then removed from the piping and tank as the fluid is circulated through a series of filters.

Why use high velocity oil flushing?

Periodic flushing is one of the best ways to ensure optimal system cleanliness and improve the health of your system.

Routine high velocity hot oil flushing is a vital part of preventive maintenance for all rotational equipment and systems. The damage that contamination can cause is well-recognised in our industry and has been linked, with certainty, to pump damage, machine failure and breakage.

By using our High Velocity Oil Flush process, our team at Bowen Fluid Engineering aims to reduce unscheduled costly downtime, minimise expenses, increase the availability of manpower by reducing regular maintenance jobs, enhance equipment reliability, and establish greater maintenance control.

After new fabrication, it's also crucial that you conduct a high velocity oil flush. After equipment breakdown or repair of piping and tubing, it is important to flush the lines to remove all foreign debris, thereby preventing premature or repeated machine failure. This will not only improve the overall performance of your system but give it a longer life.

To utilise this service for yourself please contact the Bowen team today.

Key Features

We pride ourselves on our ability to provide:

- Reliable service with minimal support required

- Fast turnaround times

- Adherence to industry and safety requirements

- Analysis and reports

- On-site flushing treatments

- Extensive knowledge and ongoing advice