Service Overview

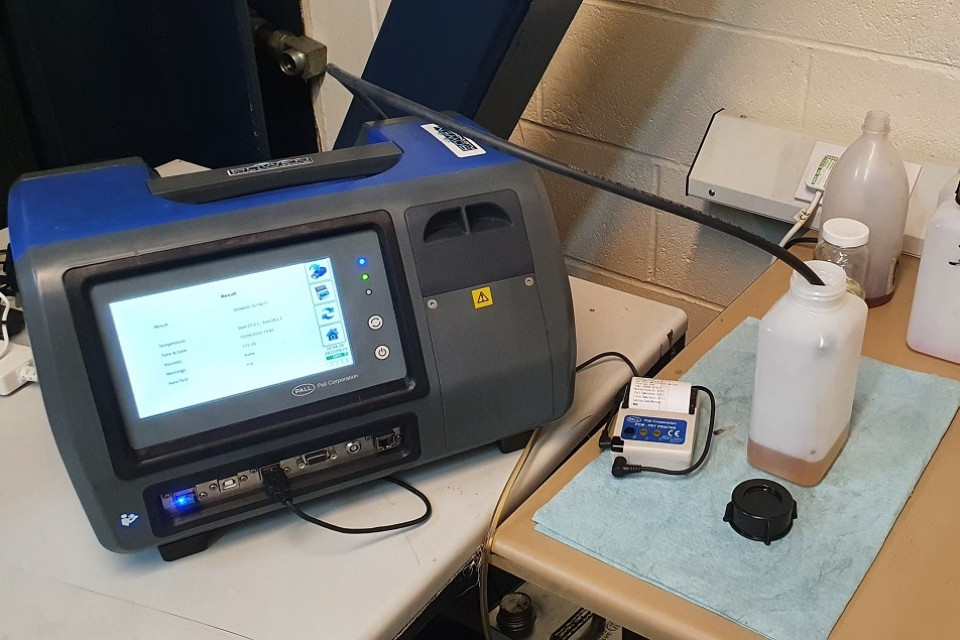

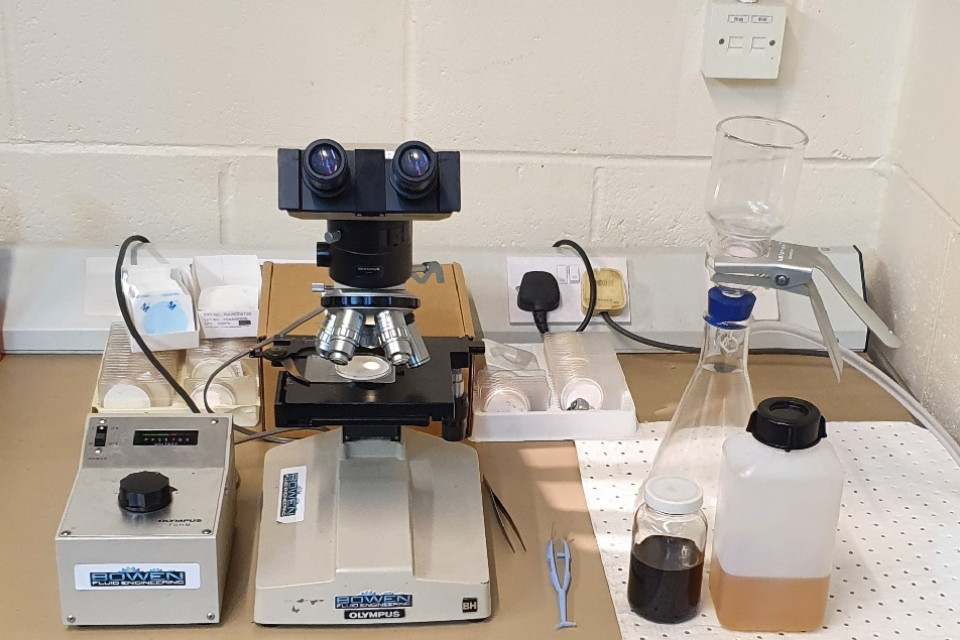

Our oil flushing service removes contaminants from your hydraulic and lube oil systems until it meets or exceeds the required cleanliness specification.

At Bowen Fluid Engineering, we have a wealth of experience in the flushing of some of the most advanced hydraulic systems. Our team has flushed a large quantity of lube oil systems for turbines and gearboxes using in-house procedures which have been developed over many years by our highly experienced engineers.

By using our oil flushing service, you'll save money in the long-term by optimising performance while decreasing system maintenance and downtime.

What is oil flushing?

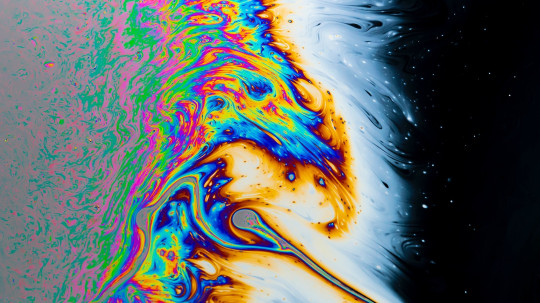

A hydraulic flush is designed to eliminate contaminants in your system. A flush consists of hot oil or a flushing fluid being circulated very rapidly through the piping of a system. This creates a turbulent flow that removes particles that would otherwise be held to the walls by laminar flow, restricting oil flow and affecting performance.

As the fluid passes through a series of high-efficiency filter elements, these particles are then removed from the piping using advanced level filtration, allowing your system to work more effectively and reducing the risk of component failure.

Benefits of oil flushing

For a hydraulic machine to function properly, any foreign matter must be routinely removed from its system. At least 75% of all hydraulic systems fail due to contaminated or ageing oil. This proves just how vital hydraulic and lube oil system flushing is in prolonging the life of expensive and key equipment.

Oil flushing is effective in removing:

- Varnish

- Debris

- Contaminated or degraded fluid

- Microbial contamination (slime, sludge etc)

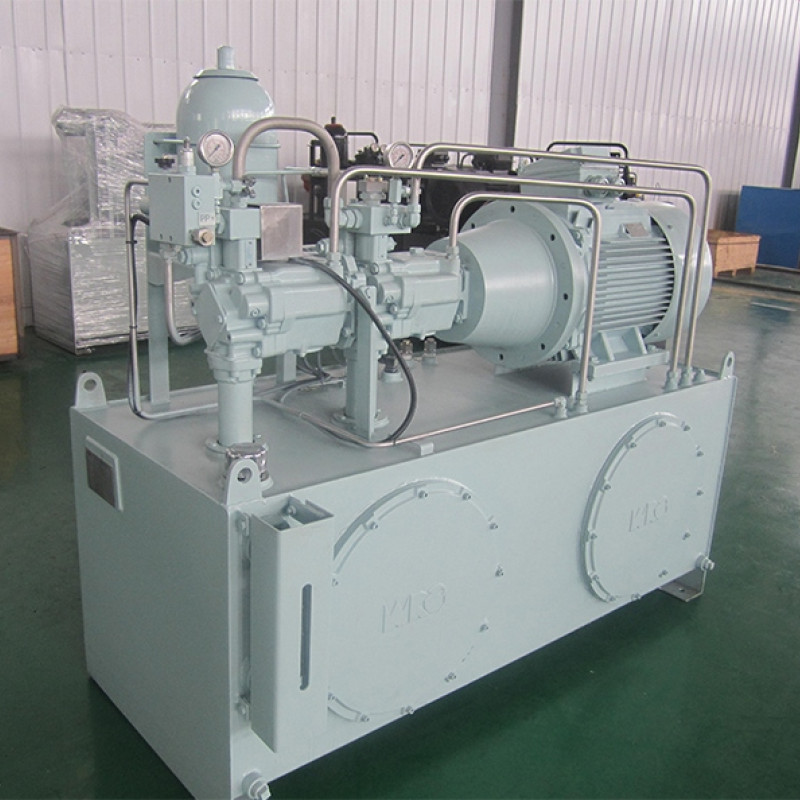

Our qualified engineers have completed all manner of jobs on a varied number of machines, including power units, pumps, turbines, gearboxes, engines and many more. With over 100 years of hydraulic experience between us, we've built up a reliable network of returning customers after years of delivering the highest quality results in the industry.

We aim to create long-lasting working relationships with our clients. Our team provides you with ongoing support, supplying hints and tips to help improve the efficacy and efficiency of your systems. All delivered in a fast turnaround, so your project stays on task.

Key features of our service

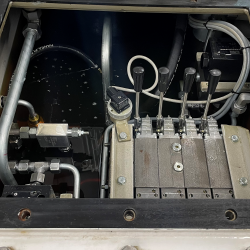

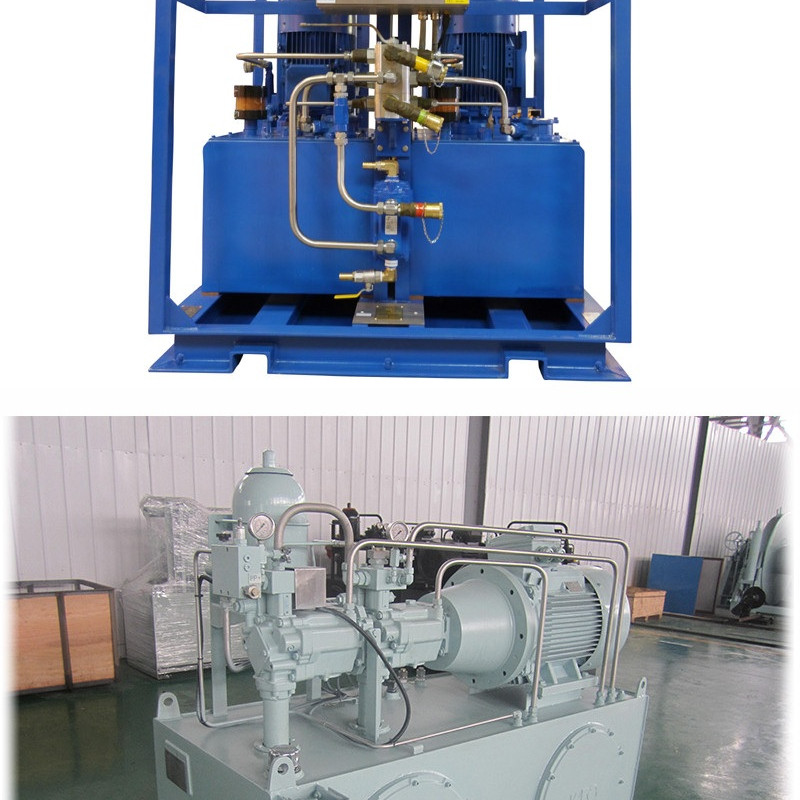

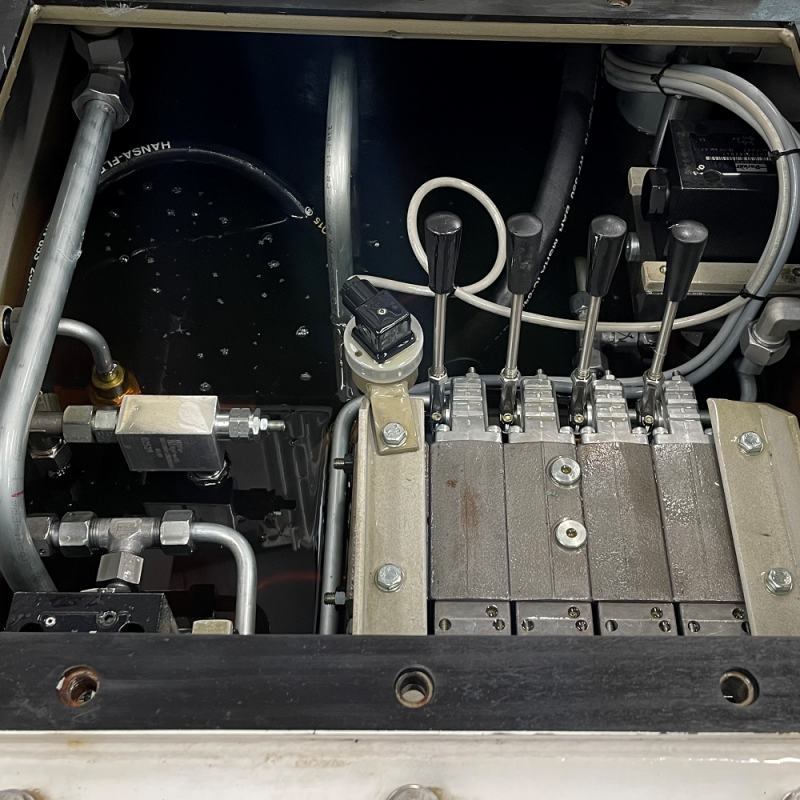

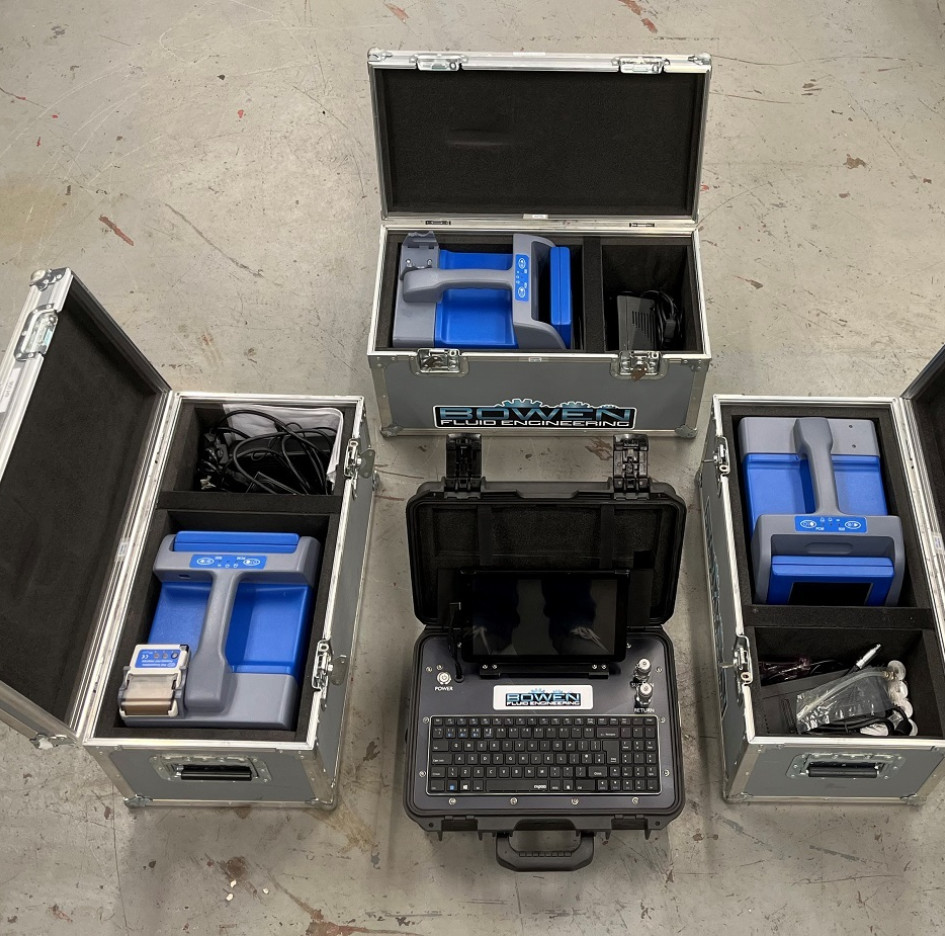

We carry out the physical oil flushing using proprietary hydraulic power units and numerous other types of pumps, dependent on the location and volume of oil to be flushed.

We offer a fuel polishing service and specialist equipment for fresh oil out the barrel, as most of the time new fresh oil straight from the barrel or container is out of spec for what most hydraulic systems require.

Contact us today if you would like to utilise our oil flushing services.

Key features of our oil flushing service include:

- Eliminates hoses of all dirt and debris that cause contamination

- Removes the need for downtime that would be required for potential repairs or damage

- Eradicates contamination from newly installed parts

- Maintains the health of your machine

Gallery