Service Overview

Our team at Bowen offers a comprehensive chemical cleaning service, resulting in a fully functioning lubricating oil system that exceeds your expectations.

We execute the cleaning of your lubrication system to remove oil varnish from pipes and tanks. This allows smoother oil flow, which in turn improves your system pressure and assists in the normal operation of your oil systems.

Based on our service, we can take preventive action for machinery and equipment operation management based on oil analysis, since only a high level of oil system cleanliness ensures the detection of the first signs of machinery and equipment wear and tear. This can help us diagnose and prevent issues such as primary pump failure and oil pressure, which can lead to your equipment going out of action.

Get in touch today for more information.

What is chemical cleaning?

Chemical cleaning is an effective method that flushes your system with a mixture of water and cleaning chemicals to remove oil varnish from pipes and tanks.

While in the past it was commonplace to simply replace the oil, as new oil dissolves much of the remaining varnish within the system, the lube oil of today has low solubility, meaning problems will quickly return after your oil has been replaced.

If your cylinder oil storage tank is big enough, it's possible to execute the cleaning of oil tank internals manually. Otherwise, a chemical cleaning between oil changes is the best solution.

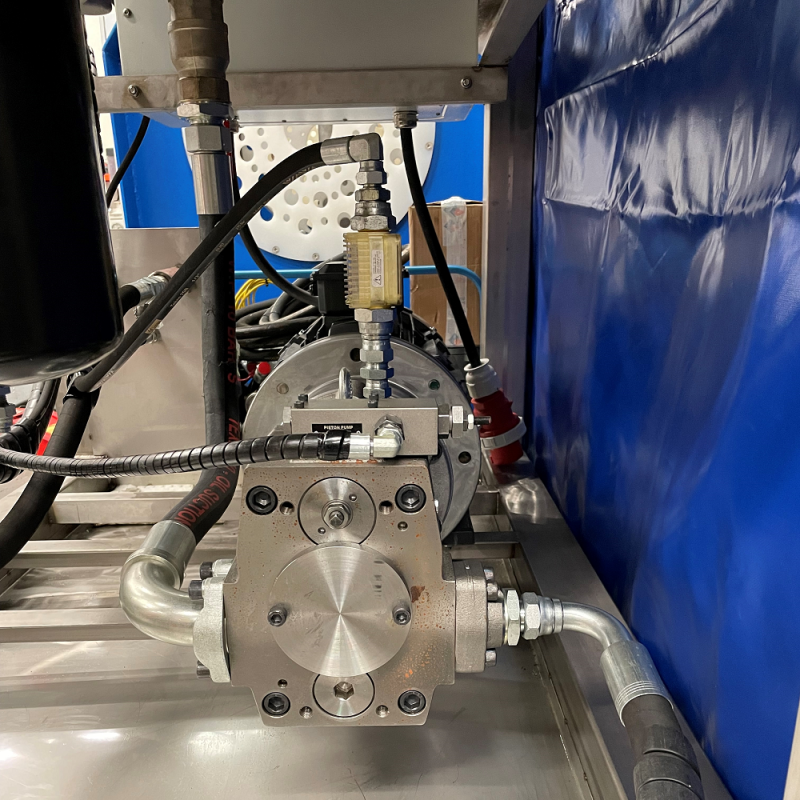

This involves flushing the system with a water-based mixture to remove chemical residues. Thus, our team will always use cleaning chemicals that are soluble in water. This process is usually performed for several hours or several days, depending on the system size and the extent of the varnish build-up on components. Afterwards, the solution is drained, and flushing skids are disconnected.

Why use chemical cleaning?

Many operators of large rotating machines encounter varnish deposits on their journal bearings. Varnish is an oil-derived deposit created under certain machine operating conditions, depending on how the oil is formulated. Nearly 10 years ago, it was reported that 1 in 3 large industrial gas turbines were showing signs of oil varnishing.

Despite this finding, varnish deposits are still one of the leading causes of downtime and damage to systems. Oil varnishing acts as an insulator, preventing lubricants from performing one of their most important functions: cooling. This contributes to the continuous temperature rise on journal bearings. Such conditions can cause unscheduled machinery downtime or bearing damage.

Performing a thorough chemical clean between oil changes is the best way to ensure your system keeps producing the high-quality results you need.

We’ll get your system running smoothly

Oil systems can be cleaned chemically to remove all varnish deposits and prevent contamination of new oil. Due to this process' complexity, however, high-level knowledge of chemistry, fluid dynamics, and filtration are required.

Our team of qualified engineers are here to help. With extensive knowledge in our field and over 100 years of experience between us, we are well versed in all hydraulic systems in the industry and can offer this service to any type of system with ease.

As a small company, we center our clients at the heart of everything that we do. We endeavor to consistently deliver the high-quality, personable and bespoke service that is now associated with our name.

Please get in touch today to discuss your requirements.