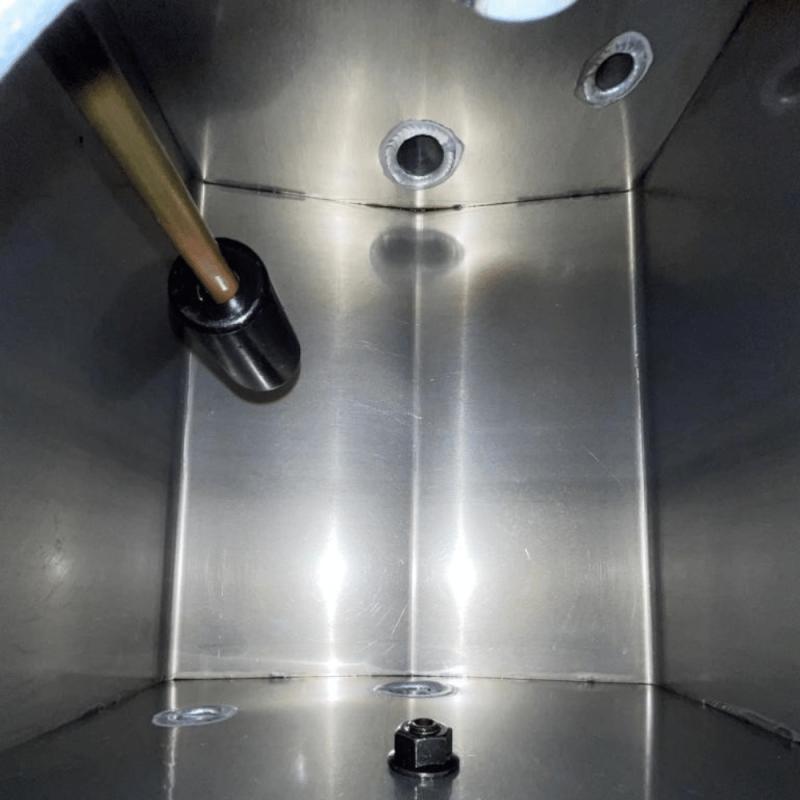

Service Overview

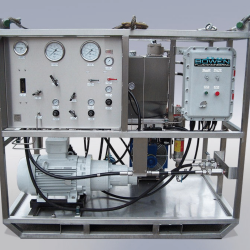

At Bowen Fluid Engineering, we understand that ensuring your machinery is working at its optimum condition is of the utmost importance. Our team is here to guarantee that any issues that may arise with your equipment are promptly dealt with, minimising downtime and helping you get the job done.

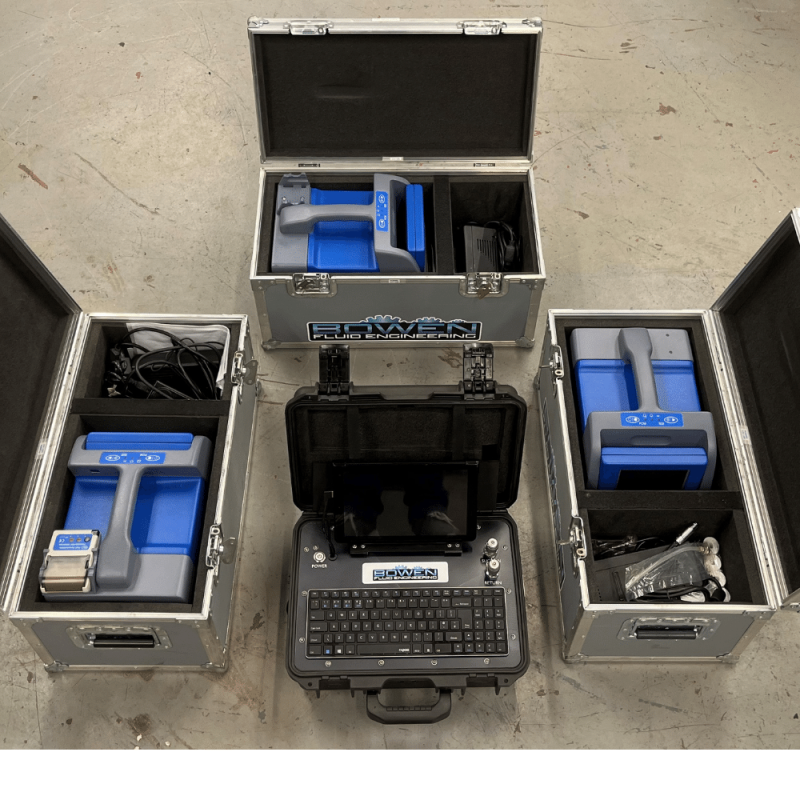

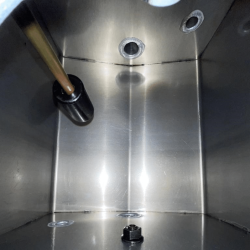

Particularly when working with a sensitive and susceptible product like hydraulics, cleanliness is vital to the performance of your machine. With our fluid and oil analysis service, you can be sure that your systems are completely free of contamination and working exactly as they should.

What is fluid analysis?

To maintain equipment health, accurate fluid monitoring is essential when working with hydraulic systems that so often operate under tight tolerances and high pressures.

For your system to perform at its best, the hydraulic fluid must have high bulk modulus (which can be found in base oil) and high viscosity index. Our fluid analysis service will test the balance of your fluid, ensuring that all elements are present and balanced to deliver the highest quality results.

Hydraulic systems are among some of the most sensitive to contamination of all oil-lubricated solutions, and so problems can quickly escalate with poor fluid conditions. This is particularly common in idle systems but can become an issue at any point during the lifespan of a machine.

Water is the biggest contaminant threat to the equilibrium of your hydraulic fluid as it can cause it to physically and/or chemically change. These breakdowns can lead to acidification, corrosion or oxidation, all of which diminish the performance of your machine.

Water also supports microbial growth, which leads to the production of slime and sludge. It decreases the thickness of the hydrodynamic film, encouraging faster and more intense component wear.

Key Features

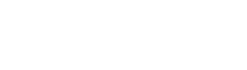

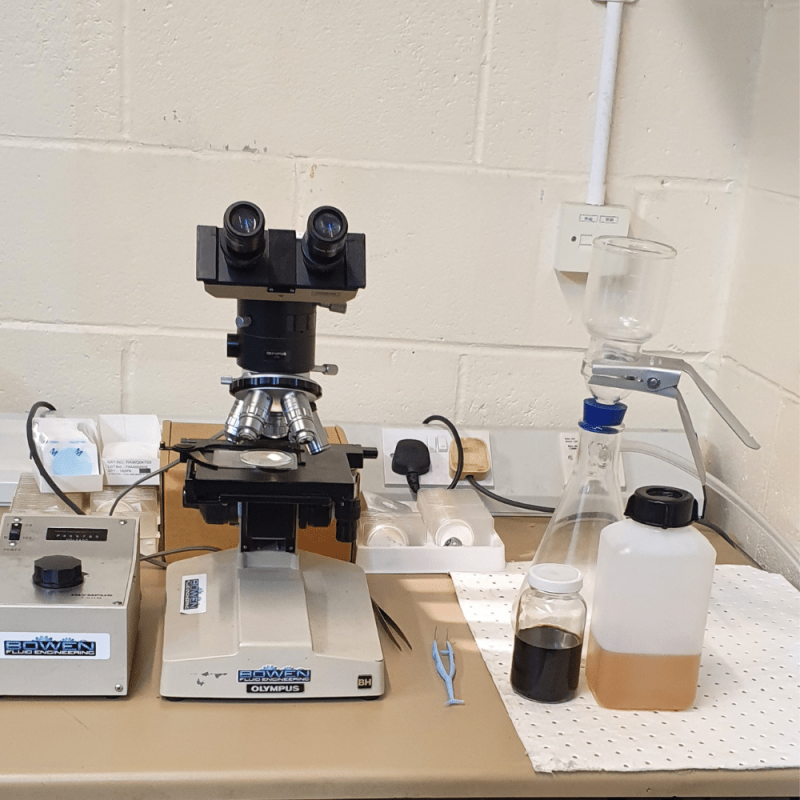

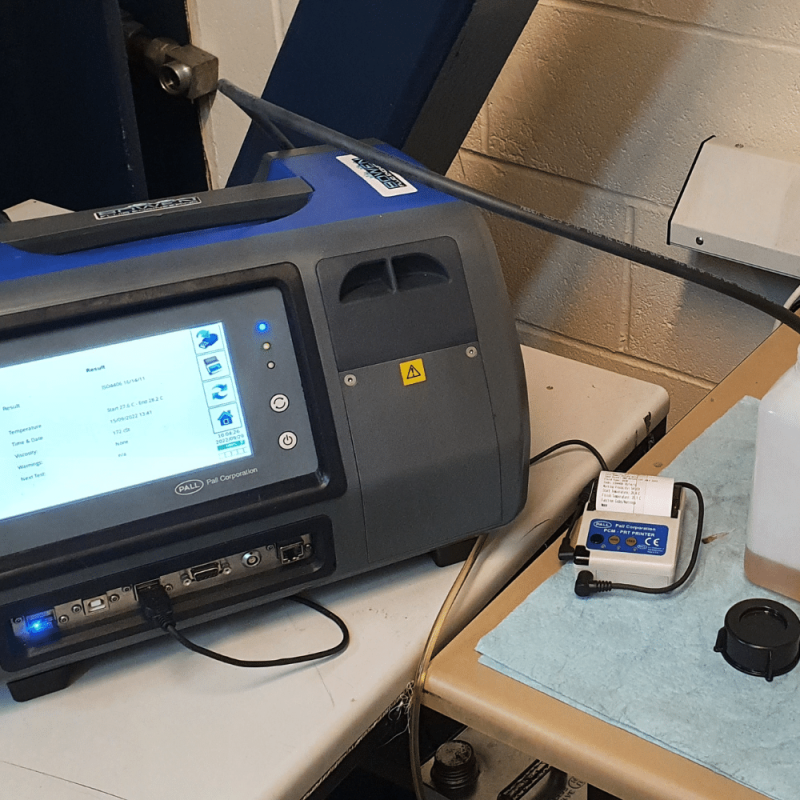

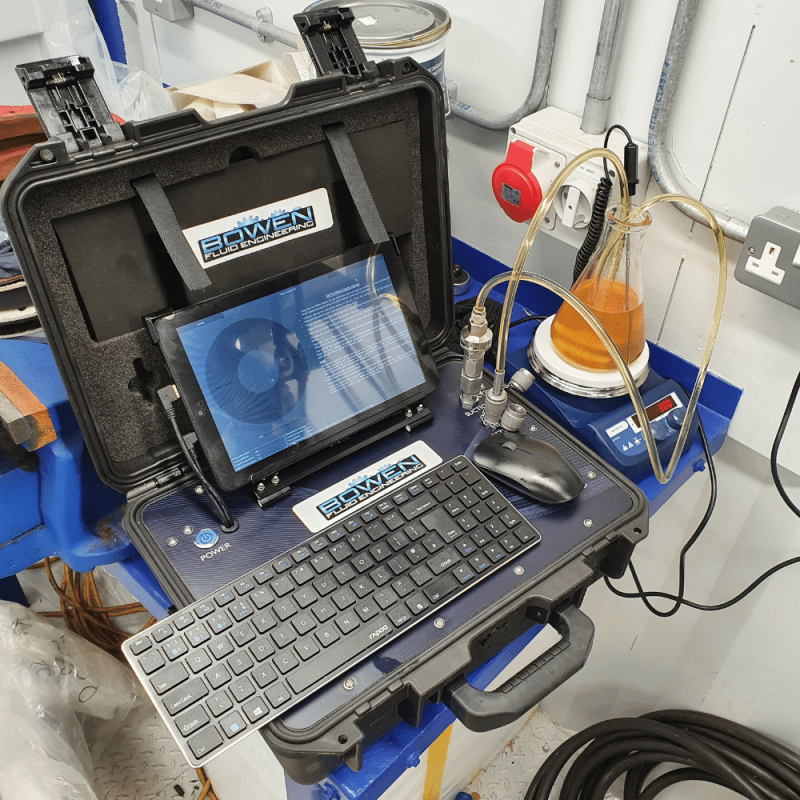

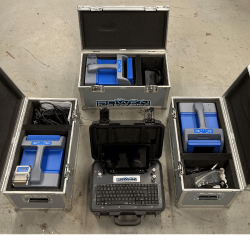

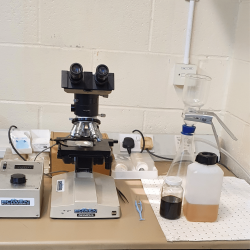

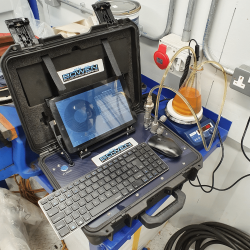

Bowen Fluid Engineering can provide you with a same-day, full and detailed oil sampling analysis. This analysis can be given as an ISO code, NAS 1638, or SAE AS4059 to meet your needs.

We also use the representative oil sample to determine the type of contamination in your oil and identify dirt ingress and verify filter performance. This will help you maintain your machine more effectively.

Perhaps most importantly, this service can identify wear and tear on equipment early on, allowing you to take steps before the problem grows too big.

- The key features of our fluid analysis service are:

- All testing carried out by experienced technicians

- Checks the cleanliness of the fluid in your system

- Diagnoses potential problems in the machine

- Helps to minimise downtime

- Assists your system in operating more effectively overall

Contact us today to take advantage of this expert service.

Benefits of our oil sampling and analysis service

Poor fluid condition is extremely common in hydraulic systems, and can significantly impede the quality of work you can do with your machine. To maintain the health of your machine components and optimise performance, we recommend regular participation in our fluid and oil analysis program.

The basic prescription for hydraulic maintenance is prevention. If you keep contaminants out of hydraulic systems, you will avoid nearly all common problems and failures. Our engineers can help you identify weaknesses in your systems, and help you to cure persistent problems with your hydraulics.

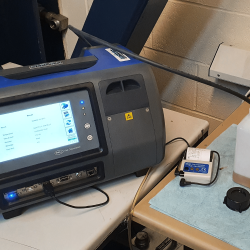

Through this service, our experienced team will monitor oxidation (metal wear, particle count, and viscosity) and contamination, lengthening the life of your machine and vastly improving its overall performance.

Key benefits of our fluid analysis services are:

- Quick turnaround

- Expert advice

- A wealth of in-house experience

- Prediction and prevention of problems

- In-depth evaluation of safety & cleanliness